CATIA V5 vs CATIA 3DEXPERIENCE

Table of contents

CATIA is a 3D CAD software extensively deployed across a wide range of industries, including automotive, aerospace, industrial equipment, consumer goods, and healthcare. Its core functionalities support the entire product development lifecycle, from conceptual design to manufacturing and beyond.

In this article, we will delve into the distinct features and benefits of CATIA V5 and CATIA 3DEXPERIENCE, providing you with the insights you need to make an informed decision that speaks to your industry and business needs.

What’s the most commonly used CATIA version?

CATIA V5 is still the most commonly used version due to its extensive adoption across various industries and its robust feature set. However, CATIA 3DEXPERIENCE is enjoying widespread popularity among companies looking to leverage cloud-based collaboration and advanced data management capabilities.

How much does CATIA cost?

Licensing for CATIA V5

CATIA V5 licensing is typically based on a perpetual license model, with costs varying depending on the modules and features required. Additional costs may include maintenance and support fees.

Licensing for CATIA 3DEXPERIENCE

CATIA 3DEXPERIENCE offers a more flexible licensing model, often based on subscriptions. This can include various roles and applications tailored to specific needs, with options for cloud-based access and collaboration.

Which CATIA version is best?

Frankly, neither CATIA V5 nor CATIA 3DEXPERIENCE is necessarily better than the other. To get the most out of your 3D CAD software, you’ll need to thoroughly evaluate your requirements and, most likely, conduct a business value assessment. But before we get to all that, let’s dig into the details and see if we can put you on the right path with some recommendations:

Main benefits of CATIA V5

Familiarity

CATIA V5 has been on the market for a long time and is widely used across various industries. Many companies have established workflows and extensive libraries of parts and assemblies in CATIA V5, making it a familiar tool for many engineers and designers. Due to its long-standing presence, there is a larger pool of experienced CATIA V5 users, which can be advantageous for training new employees and maintaining consistency in design processes.

File-based system

CATIA V5 operates on a file-based system, which can be simpler to manage for smaller teams or projects that do not require extensive collaboration or data management capabilities. Users can work independently without relying on a centralized database, which can be beneficial in environments where internet connectivity is unreliable or where there are concerns about data security in the cloud.

Integration with existing PDM

CATIA V5 can integrate with various product data management (PDM) and product lifecycle management (PLM) systems, including 3DEXPERIENCE itself, though typically through additional programs. This allows companies to leverage their existing infrastructure and avoid the complexities of transitioning to a new system.

Cost considerations

For some organizations, the licensing model of CATIA V5 may be more cost-effective compared to the subscription-based model of CATIA 3DEXPERIENCE, especially if they already own perpetual licenses for V5.

Offline capabilities

Since CATIA V5 is not dependent on cloud services, it allows users to work offline, which can be crucial for projects in remote locations or in industries where internet access is restricted for security reasons.

Established customizations

Many companies have developed custom scripts, macros, and add-ons for CATIA V5 over the years. Transitioning to a new platform can require significant effort to replicate these customizations. That being said, we’ve had a lot of experience in this area, to the extent that we’ve developed add-on software for both CATIA and 3DEXPERIENCE, covering applications ranging from quality and compliance to system integrations.

Main benefits of CATIA 3DEXPERIENCE

Before we get into some of the major advantages that CATIA 3DEXPERIENCE has over its predecessor, it’s important to provide a bit of context about the 3DEXPERIENCE platform and its purpose.

What’s the purpose of 3DEXPERIENCE?

The 3DEXPERIENCE platform is designed to transform the way businesses innovate and operate. It connects people, processes, and data, creating a seamless collaborative environment for sustainable innovation. The 3DEXPERIENCE platform performs four essential functions:

- It offers a real-time, holistic view of business activities and ecosystems.

- It facilitates secure, real-time collaboration across teams and departments, regardless of location.

- It supports innovation by integrating design, simulation, and data management tools.

- It helps businesses achieve sustainability goals by optimizing processes and reducing waste.

Database document management

With CATIA connected to the 3DEXPERIENCE platform, you’re able to enjoy all the benefits that you’d expect from product data management (PDM). Version management, modification rights, release control, etc. are all present and configurable to your organizational needs.

This means that, in addition to all the other features described below, CATIA users migrating from file-based CATIA V5 to CATIA 3DEXPERIENCE will be able to work much more efficiently. All the issues associated with managing collaborative work, such as manually copying files, trying to manage revisions, and accidentally overwriting others’ work, are gone in favor of a single source of truth.

Infrastructure changes

Simply put, CATIA 3DEXPERIENCE works quicker by taking advantage of a computer’s resources far more effectively than CATIA V5, reducing the waiting times for rendering, loading large assemblies, and performing complicated mathematics.

This affects virtually every operation CATIA makes, contributing to substantial time savings for every user.

It’s designed to be hosted on the web from the ground up, meaning that you’ll transmit and receive data optimized for your current network state, whether you’re on a public connection, or your local network.

When opening assemblies, CATIA only requests the data it needs. It’ll load your assembly’s component parts only when you specify. In CATIA V5, you can use cache mode to do something similar. The major difference here is that a server process creates any required lightweight files for the process beforehand, meaning that your assemblies will load even faster.

The web-based nature of ENOVIA makes it easy for users to connect their session to the database, encrypted from anywhere, without the need for complex setup on each client machine. This makes collaboration between different sites or businesses convenient.

Just like CATIA V5, CATIA 3DEXPERIENCE is a client application installed on a user’s PC. It communicates with the 3DEXPERIENCE platform via an internet-compatible connection (non-CATIA users connect through a browser).

Searching and exploring 3D structures

Even with a PDM system managing data, users often find it cumbersome to fill out search forms for every part or assembly, especially when using an external program. CATIA 3DEXPERIENCE, however, simplifies this process with an ever-present full-text search bar that can locate any accessible item on the platform in one go while still offering precise filtering tools.

Additionally, users can set up lists of favorites and folders to organize their work. The database’s handling of data allows designers to create any folders or favorites they need without affecting how other users access the data. This contrasts sharply with CATIA V5’s file-based system, where moving files into different folders can break links between files, causing significant frustration.

All 3DEXPERIENCE rich client applications enable users to explore the visual structure of assemblies quickly in a lightweight mode without needing to open the full design data. This feature allows both CAD and non-CAD users to view the structure of assemblies from the top levels and find the parts they need without requiring a powerful computer to open top-level assemblies in full design mode.

While other PDM systems offer similar capabilities, they often depend on CAD users constantly opening and updating top-level assemblies to keep viewer files current. The 3DEXPERIENCE platform, however, automatically recognizes changes to parts and updates all affected representations, ensuring all stakeholders have the most accurate view of the structure.

On top of that, the data stored in 3DEXPERIENCE can be enhanced by attaching various file types directly to the CAD data, such as reference tables and exported PDFs. This documentation is fully database-controlled and is released alongside the CAD data it is attached to.

Finally, the database can visually color 3D objects based on customizable parameters, such as identifying whether objects are released, obsolete, or still in work. This visual aid helps users quickly understand the status of different components within the assembly.

Integrated database control

CATIA V5 can integrate with various PDM and PLM systems, including 3DEXPERIENCE itself. However, this typically requires a separate program installed on top of CATIA, which is used to search for objects and load the required files locally.

While functional and an improvement over file-based CATIA, this setup shares several limitations:

- User interface: There is a clear separation between the PDM system and CATIA V5, resulting in an unintuitive interface that requires switching between two programs to find, open, and save data.

- Complex mappings: Setting up complex mappings between CATIA V5 properties and database attributes is necessary, and these properties must be synchronized with the database. Users have the freedom to modify any CATIA property, which can lead to inconsistencies.

- Drawing management: Drawings are considered parents of parts and assemblies, so locating a drawing for a part already in session requires additional database searches.

- Revision handling: Multiple revisions of the same part or assembly must have the same filename, making it difficult to compare versions. CATIA V5 cannot handle the same filename loaded into a session more than once, complicating high-level assembly management.

- Local storage risks: Since CATIA V5 files need to be stored locally, users could potentially work outside of database control, send uncontrolled copies of drawings, or even compromise company data.

In contrast, the 3DEXPERIENCE platform eliminates these issues:

- Unified interface: The user interface in CATIA 3DEXPERIENCE is fully integrated with the database, eliminating the need for separate programs and complex mappings.

- Revision management: Multiple revisions of the same object can coexist in a session without any problems.

- Drawing integration: Drawings are directly associated with the parts and products they represent, making it easy to find and open relevant drawings.

- Secure data transfer: Data transferred to CAD machines is encrypted and specific to the CATIA 3DEXPERIENCE session and database, with controlled permissions for exporting files in other formats.

Better link management

In a file-based operation, design departments often struggle with the visibility of links between CATIA files. These links are only visible in one direction—from the files using linked copies of the data to the files where that data was originally created. This limitation makes it impossible to interrogate a file and determine which parts, assemblies, and drawings rely on it. Consequently, if someone moves the file or modifies critical geometry, it can inadvertently disrupt any other file dependent on the altered part.

While existing database PDM systems mitigate this issue by eliminating the need for users to move files and enabling them to identify links between objects, CATIA 3DEXPERIENCE offers a more advanced solution.

CATIA 3DEXPERIENCE allows users to identify the exact features being used and their locations in any given object. This includes geometry links, publication links, contextual links, material links, and drawing links.

Importantly, these links can be identified without fully opening the object in a session, allowing even non-CAD users to understand and appreciate the dependencies between parts. This comprehensive visibility ensures that all stakeholders can manage and maintain the integrity of their designs effectively.

New and improved workbenches

CATIA 3DEXPERIENCE features various new workspaces that exploit the new database functionalities and new graphical capabilities of the CATIA engine. New Workbenches include Natural Sketch, which allows non-CAD users to create concept designs by intuitively drawing on 2D planes in 3D space, creating wireframe geometry that can be directly used by CATIA designers to then create full design specifications.

Existing Workbenches have been modified to directly query the ENOVIA database for its information rather than the local data, meaning that the data you work with is always up-to-date.

3D BOM management

Typically, a PLM system allows you to create a separate BOM tree from the CATIA structure, with the BOM manager overseeing the reconfiguration of this BOM to the real purchased BOM. However, the BOM and the CAD tree seldom agree with each other, and need to be synchronized frequently and often manually, leading to a long-standing rivalry between the engineering and design teams.

3DEXPERIENCE solves this by having one tree handle the 3D models from all connected CAD tools, along with the engineering requirements.

Within CATIA 3DEXPERIENCE, designers can declare which components they have used that are not to be included in the BOM or are phantom assemblies, reducing the amount of time spent querying which parts are necessary in the BOM.

Engineers and designers both have access to the same tree for modification without needing a CAD license, as long as they don’t need to model parts.

Proper assembly representation management

Assemblies often involve more than just the sum of their individual parts. Various operations, such as drilling new holes or grinding down surfaces, are performed after the parts have been assembled. In many CAD systems, including CATIA V5, it can be challenging to accurately represent both the individual parts and the finished assembly. This typically requires creating a “skeleton” part to depict the completed assembly.

CATIA 3DEXPERIENCE improves this process with a feature called “Derived Representation.” This function allows geometry to be inserted directly into the assembly, copying all necessary geometry into a single representation. This enables post-assembly operations to be specified without the need for dummy part numbers.

Additionally, the ability to insert geometry directly into assemblies eliminates the need for creating skeleton parts to contain construction geometry for assemblies, such as patterns, package boundaries, and centerlines. This streamlined approach simplifies the design process and ensures a more accurate representation of the final product.

Graphical improvements

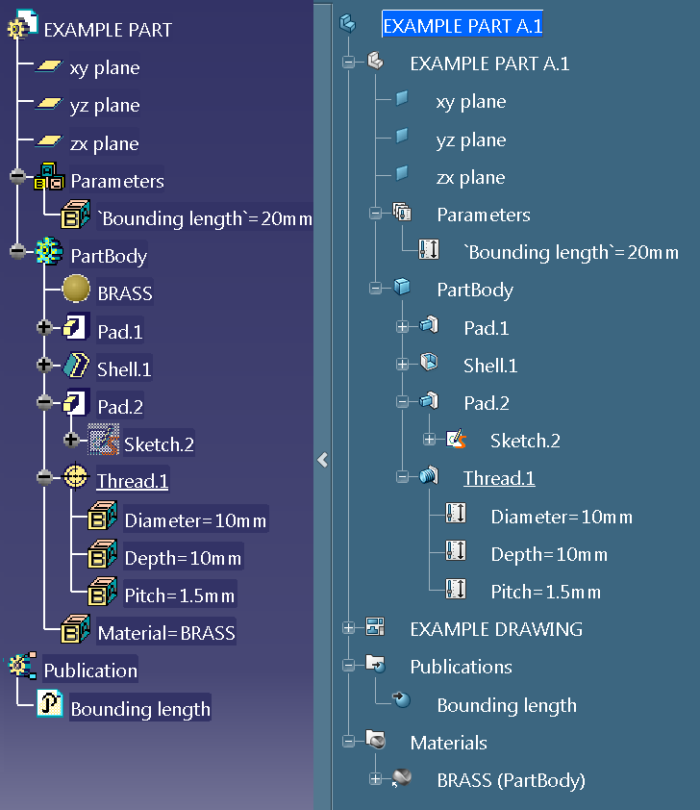

In addition to numerous technical enhancements, CATIA 3DEXPERIENCE boasts a significantly improved user interface designed to optimize the user experience. The graphical assets have been re-created to take full advantage of high-resolution screens while considerably reducing visual clutter.

This modernized interface not only looks more polished, but also enhances usability and efficiency. To illustrate the update, compare the trees from CATIA V5 and CATIA 3DEXPERIENCE. Despite the visual enhancements, designers will still recognize all the features of the tree, ensuring familiarity while benefiting from a more modern and efficient interface.

Recommendations

While Dassault Systèmes has made fundamental enhancements to the data structure behind the software, the CATIA 3DEXPERIENCE modeling tools will be familiar to any experienced CATIA V5 user. The major difference to the user experience is the enhancement of existing tools and a few additional workbenches.

The underlying kernel for CATIA 3DEXPERIENCE is based on the V5 kernel. This means that data from V5 can be imported, with full history and links of all kinds, into 3DEXPERIENCE with the database.

It has the additional ability to recognize when files have already been imported and re-link these files to any new data, preventing unnecessary duplicates. Imported data can even be updated with newer versions of V5 data at a later date. So, after the import, users can simply pick up their work where they left off.

Why choose CATIA V5?

CATIA V5 is ideal for organizations with extensive legacy systems and existing workflows that rely heavily on file-based operations. It’s also suitable for smaller teams or projects where the simplicity of a file-based system is advantageous.

Why choose CATIA 3DEXPERIENCE?

CATIA 3DEXPERIENCE is best suited to organizations seeking enhanced collaboration and robust data management. It’s particularly beneficial for global teams requiring scalable solutions or working in industries with stringent process and product regulations.

Key Considerations

Here’s a handy checklist you can share with key stakeholders when looking into your CATIA deployment. Feel free to reach out to one of our CATIA experts, who’ll be happy to help you understand your requirements and even conduct a business value assessment.

Existing infrastructure and legacy systems

- Compatibility with current systems

- Integration with PDM/PLM systems

Collaboration and data management

- File-based vs database-driven

- Remote and global collaboration

User experience and interface

- Familiarity and learning curve

Performance and resource use

- System requirements

- Cloud computing

Cost and licensing

- Licensing models

- Total cost of ownership

Future-proofing and scalability

- Migration and/or updates

Security and compliance

- Data security

- On-premise vs cloud

Discover CATIA 3DEXPERIENCE with your 3-month trial for just 330€ for 3 months!