What is Non-Linear Analysis?

Table of contents

What is Linear?

In order to create a numerical or even mental model of a system or component it is necessary to adopt a few simplifications. Things you assume don’t matter, and things that, by clearing them out of the way, provide an enhanced view of what’s going on. And in structural mechanics what you mainly clear out is the non-linear stuff. You assume that if you double the load you double the deflection, and that doubling of the deflection results in a doubling of the stress level. To date most finite element models have been built using those assumptions, and I’d guess that most still are.

The problem with the big linearity assumption is that it simply isn’t true. Nothing is actually completely linear. At this point I can hear people saying that it’s been good enough up until now, and more. And to some extent they are correct. There are plenty of cases where the linear assumption is more than adequate to model performance and provide an assurance of safety and general OKness. But critically there are also cases where it isn’t, and still others where forcing enhanced performance and efficiency from the latest and greatest design variant requires a more detailed understanding of the physics and processes which go to make up what the thing actually does. Nobody gets into non-linear simulation without a very good reason, but reasons there are aplenty. And the rewards are there too.

This possibly isn’t the sort of medium to get into detailed treatises on the non-linear response of systems and components. But it is probably OK to look at a few things that spoil the simplified linear party. So lets start off with materials.

What is Non-Linear?

Everyone has experienced non-linear materials at some point. Grab a rubber band and pull it. At first it takes a bit of effort to stretch, then suddenly you get loads of movement with little additional effort. Pull it a bit more and it seems to have become more resistant again. The response of the material is a function of how much stress it has already seen. Something similar happens when you overload a piece of steel. Further; when you overload it, not only does the response become non-linear but it also results in a permanent deformation. In the portion of the response that is non-linear, and responsible for permanent shape change, a lot of energy is absorbed – good news if you are in a car accident or a panel beater. The interesting thing is how to characterise this oddness in a CAE program, but that’s something for another time and place.

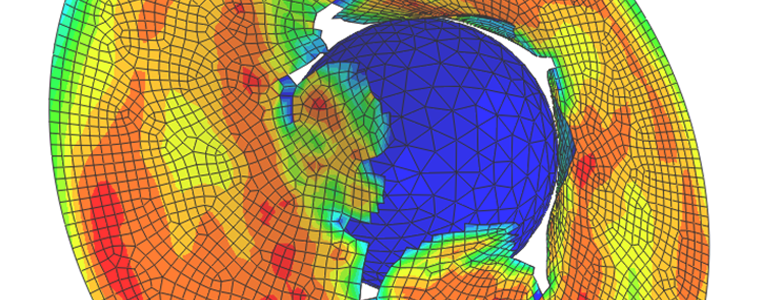

It’s not just materials that spoil the linear party. The way in which parts interact with each other – contact in FEA speak – is another source of non-linearity, as is deflecting a lot and changing shape. Add rapid dynamic loading and you get the full set of physical effects which can cause the deflection to lose its direction relationship with load.

It’s a common misconception that simulation systems know to consider this stuff without being told. They don’t and probably couldn’t in any practical scenario. In hindsight at least its obvious that going non-linear isn’t without its pain-points and plain, simple, hard work. But in reward what do we get? For starters it’s products which work more effectively and more predictably across a wider range of service cases. But it ends up with one thing. Enhanced product knowledge. And surely that is the biggest reward a designer can have.