What is Product Lifecycle Management (PLM)?

Table of contents

- What is Product Lifecycle Management (PLM)?

- What is the PLM Definition of a Product?

- What is a Product Lifecycle?

- How Do You Manage a Product Lifecycle?

- What is a PLM Platform?

- What is Lifecycle Analysis?

- Digitalization, Digital Transformation, & Cloud Data Migration

- What Are the Current Trends in PLM?

- What is CAD (Computer Aided Design)?

- What is CAE (Computer Aided Engineering)?

- What is CAM (Computer Aided Manufacture)?

- What is Project Management?

- What Can I Achieve with ENOVIA?

- How Does ENOVIA Support Project Management?

- What is Digital Manufacturing?

- What is a Digital Twin?

- What is DELMIA 3DEXPERIENCE?

- What is 3DEXPERIENCE?

- How to Implement a PLM Solution

What is Product Lifecycle Management (PLM)?

“A philosophy, process and discipline supported by software for managing products through the stages of their life cycles, from concept through retirement. As a discipline, it has grown from a mechanical design and engineering focus to being applied to many different vertical-industry product development challenges.”

More than simply software, PLM is a holistic approach to product development. It incorporates every aspect of a product’s lifecycle – from innovation through to repurposing, reuse and recycling.

PLM platforms are suites of connected software bringing together people, processes and data, creating a seamless collaborative environment. And making product creation simple, successful and sustainable.

But the platform itself is only a set of tools that support your teams in their individual roles. When implementing PLM in your organization, each of your teams should be prepared to take on an entirely new approach to product development.

So, let’s break down each phase of a product’s lifecycle and see how PLM supports, enables and enhances your teams’ performances.

What is the PLM Definition of a Product?

When we take the word ‘product’ separately from the rest, the question is: what is a product? If we open the dictionary, we see that a product is economically all that can be offered on the market to meet a demand. This can be tangible, such as an item in a shop, but also a service.

Many think that PLM is only used within the car or aircraft industry. However, PLM is widely used within many different industries.

One of our customers in the travel industry wanted to use PLM to improve the configuration of travel. But we also have customers within the retail sector, where PLM is indispensable for developing seasonal clothing or accessories lines.

A quick go-to-market, improving mass production, simplicity in portfolio management and preparing marketing is of great importance.

What is a Product Lifecycle?

Innovation & Design

The product lifecycle begins with a basic concept or idea. Here, new product ideas are explored, and the most promising ones are selected for development. Innovators design new and improved product solutions, bringing your product to the level of maturity necessary to begin design development.

The design stage of product development covers a range of engineering disciplines. During this development phase, product designs are matured, materials are selected and both virtual and real prototypes are created for testing until they meet the respective operating conditions. Most importantly, this phase is repeated to ensure that customer requirements are met with a well-defined product.

Data Management, Governance, & Simulation

CAD Data Management enables organizations to easily access detailed product design information, making the most of current and historic design versions. This product data, your organization’s Intellectual Property (IP), is kept secure and accessed only by those with appropriate permissions.

Next, validation, simulation and optimization tools and used to perform various product tests. These range from Stress Analyses to Finite Element Analysis or Computational Fluid Dynamics. Digital twins provide a fully functional simulation model of your product. These can react to real time data and provide invaluable insight when it comes to real world analysis of your product.

Manufacturing & Marketing

After your design is complete, product manufacturing begins. This phase is defined by the tools and methods used to produce your product. PLM tools such as Production Planning, enable organizations to develop more agile and efficient production processes. This phase is key to achieving a faster time-to-market. And to manufacturing a successful product at launch.

Next, a marketing strategy is developed to identify your key target audience. Various communication modes and methods are applied to convey your unique product vision. PLM solutions provide comprehensive tools to support marketing teams in bringing your product to market.

Maintenance & Repurposing

But this is not the end of the story. Companies continue to collect feedback on the product in order to maintain and optimize future product versions. This valuable product data is used to report on real world performance.

Maintenance, repair and operations tools enable you to provide vital in-service support to your customers. And this information can also be used to prepare your product for the next phase of its lifecycle.

PLM platforms enable organizations to participate in the circular economy, maintaining value in the product lifecycle, by providing the necessary tools to close the manufacturing loop. PLM can even help you to recycle, reuse and repurpose component parts of your product at the end of its lifecycle. This helps to reduce waste and can even cut back resource outlay in future product development. And, where materials are unable to be repurposed, PLM helps to ensure the responsible handling of waste.

How Do You Manage a Product Lifecycle?

Management is a broad concept that touches multiple facets. At TECHNIA, for example, we mean Project Management. This is often about design, data, how to deal with milestones and planning projects. In fact, this includes everything about the development of a product.

Another component that also falls under Management is being able to work together in a structured way both internally and externally. So, you want to get a grip on these collaborations and be able to scale them up so far that you can work together easily, even internationally.

Process Management is about how a product should be developed and what product information is related to it. For example, certifications, product documentation, manuals and change processes.

Last, but not least, Change Management tackles the way that changes pass through an organization. This is best captured in a workflow. This is a great way to create insights for employees regarding their tasks and responsibilities.

What is a PLM Platform?

Product Lifecycle Management platforms provide solutions for an array of disciplines – Engineering and Design, Manufacturing, Simulation and more. And, as each of these areas encompass various specialisms, it makes sense to provide specialist software tools for them.

So, a PLM platform may connect Computer-Aided Design (CAD) software suites such as CATIA or SOLIDWORKS with Computer-Aided Manufacturing (CAM) software suites such as DELMIA. And the PLM platform ecosystem connects all applications, tools and software available for use in conjunction with your PLM platform.

This may refer to products developed and managed by the platform provider, or by developers working alongside them. For example, TECHNIA Software’s Experience Packaged suite is part of the 3DEXPERIENCE platform ecosystem – these are tools and applications which complement the 3DEXPERIENCE platform.

This means that every speck of data concerning your product is communicated live from a single source of truth. Every team member, wherever they are, has access to the same data and they’re able to update, revise and discuss that data in real time. So, PLM platforms provide a cohesive ecosystem in which your organisation, culture and business model can collaborate efficiently and thrive.

Manufacturers benefit from working within a PLM platform ecosystem in many ways. These vary from industry to industry. But there are three key reasons that PLM platform implementations can benefit any organization.

Firstly, PLM platforms bring together people, processes and data. Meaning that your organizational Intellectual Property (IP) is centralized, and readily available to all permissible users at any given time. This ensures that all communication and action concerning your product is as relevant and efficient as possible.

Secondly, investing in a PLM platform ecosystem enables you to expand or streamline areas of your organization as you require. This is made more easily attainable with PLM platforms on Cloud – as application licenses can be made available according to, and on demand.

Thirdly, working within a common PLM platform enables simple supplier collaboration. this means that your suppliers can be granted access to relevant, live data just as easily as your own teams can. Simply put, you’re sharing the benefits of your PLM platform with the organizations you work with.

PLM is a Holistic Approach to People, Processes & Data

We say that PLM brings together people, processes and data. Because PLM is more than any individual phase of the product lifecycle. It’s about ensuring that valuable, valid data is accessible to the right people, and applied to the right process. No matter where, when or how that data is needed.

So, when used correctly, PLM supports global collaboration throughout your organisation. In fact, PLM even supports collaboration outside of your organization for supply chain management and more.

It can help individuals across your organization become more efficient, to better visualize complex processes, and to ensure the security of intellectual property (IP).

It can even help you to determine whether a product has successfully moved between stages of development. Whether there might be delays, and how you can efficiently plan changes in any aspect of development.

PLM is a Seamless Collaborative Environment

PLM provides the right tools for your product in a targeted and effective manner as it moves through the various development phases. For example,

Computer Aided Design (CAD) tools allow you to create parametric models that can be quickly customized as needed.

Computer Aided Engineering (CAE) tools allow you to simulate and test your design in a virtual, realistic environment.

Computer Aided Manufacturing (CAM) tools enable virtual manufacturing and enable engineers to identify potential manufacturing problems before building a manufacturing facility.

What is Lifecycle Analysis?

From sourcing raw materials to delivering completed items, Lifecycle Assessment (LCA) provides a cohesive overview of the effect your company’s products and services have on the environment. It asks questions about product design and material choice optimization, manufacturing processes, and distribution methods. LCA addresses concerns like these based on reliable data collated from thousands of sources within your business.

Traditional LCA assesses the impact of previous actions and is distinct from day-to-day company operations. LCA, on the other hand, can accomplish so much more with enhanced digitalization.

Digitalization, Digital Transformation, & Cloud Data Migration

Gartner Group define digitalization as:

“The use of digital technologies to change a business model and provide new revenue and value-producing opportunities; it is the process of moving to a digital business.”

So, digitalization refers to a strategic, digital approach to modern business. Whereas digital transformation is a broader term refering to the process of integrating digital technology into all aspects of a business in order to better connect with customers, improve efficiency, and create new opportunities.

These are critical strategies for any organization aiming to remain competitive in the digital landscape. Expected benefits of digitalization and cloud data migration include:

- Improved efficiency by allowing you to access data and applications from anywhere

- Scalability without the need to invest in additional hardware or software

- Flexibility to quickly and easily adapt to changes in demand

Check out our quick guides to cloud data migration, and digital transformation as a strategy for sustainable product creation.

What Are the Current Trends in PLM?

Franke Meijers | PLM Consultant

“PLM is constantly evolving in all its facets. For example, the design philosophy, “Cradle-to-Cradle” is increasingly linked to PLM. This philosophy states that every raw material, and materials used for a product, must also be reused. The extra dimension of this idea is that the raw material should not lose value when reused. Recycling and upcycling are becoming an essential part of the traditional design process.

Another development is that organizations have increasingly unique lifecycles. The traditional picture is, of course, when companies do their own development; have their own production; and also provide services for their product. But this is not always the case. This means that working together with different organisations and suppliers plays a big role. This cooperation should be seamless and have a very low margin of error.

We are also seeing a shift in business models where PLM can make its appearance.

Think of product as a service and lease models. In these cases, the product is not in possession, but a service is taken to use the product. This gives a completely different view of product development because it becomes essential to extend the life of a product. Preventive and predictive maintenance will then become invaluable.”

Engineering & Design

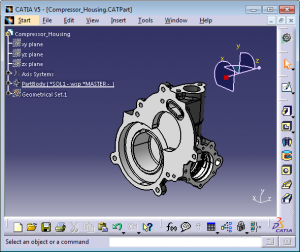

What is CAD (Computer Aided Design)?

Enabling 2D and 3D design

Computer-Aided Design is most employed by Engineers to help create, modify and/or analyze graphical representations of product designs. Its applications stretch across a multitude of industries due to its many popular benefits.

CAD software innovation continues to improve the quality of design through greater accuracy and the reduction of design errors. CAD software is also capable of improving communication due the centralization of design data and documentation, creating a single source of truth for engineers and manufacturers.

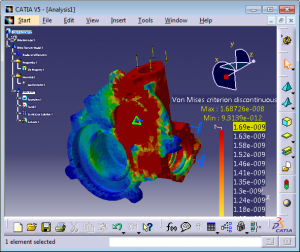

What is CAE (Computer Aided Engineering)?

Enabling verification through analysis of 3D models

Computer-aided engineering most used by Engineers for the simulation and analysis of product designs. These analyses commonly include Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), and Multibody Dynamics (MBD). Similar to prototyping, these processes help to prepare a product design for real world stresses. This testing enables Engineers to make better product design decisions and revisions – this ultimately leads to better product performance and customer experiences.

What is CAM (Computer Aided Manufacture)?

Enabling manufacturing processes to be designed for 3D model manufacture

Computer-aided manufacturing is commonly used by Manufacturers – rather than Design Engineers – to plan, manage, control and automate manufacturing operations. CAM software uses CAD designs to infer machining instructions while optimizing part production efficiency and material usage.

Some PLM systems available on the market today, such as the 3DEXPERIENCE platform, provide single sign-on access to multiple CAD, CAE, and CAM tools. This improves productivity and efficiency by working on the same data from different people at each stage of product development. The single sign-on platform also functions as a central database and avoids duplication of data. So, everyone connected to the platform can access the latest data at any time, and their changes are immediately available to everyone else with access. This allows stakeholders to review and verify changes, bringing the product to the next stage of its lifecycle.

What is Project Management?

Project Management is a methodical approach to the planning, organization, controlling of resources, and execution of a project from start to finish.

In PLM, Project Management is primarily about realizing a product vision. Successful project management can be defined by the achievement of clear business goals. These will include Key Performance Indicators (KPIs) such as ensuring Return-On-Investment (ROI), or meeting/exceeding End-User requirements.

What Can I Achieve with ENOVIA?

Lend support to your teams improving product quality, reducing rework time, meeting quality and compliance standards and, ultimately, bringing better products to market ahead of the competition.

Give team members the best tools for the task with role-based functionality and customizable dashboards. Update and review files and data anytime, anywhere with cloud-based solutions for ENOVIA on the 3DEXPERIENCE platform.

ENOVIA supports three main disciplines: Business Modelling & Planning, Quality and Compliance Management, and Product Configurations. Ultimately, its purpose is to help guide your product throughout its lifecycle.

Continue reading about ENOVIA here

How Does ENOVIA Support Project Management?

Successful project management happens when your organization truly works together. But it’s hard to imagine how a global organization might achieve this kind of dynamic collaboration between tens, hundreds or thousands of users. And that’s before we even begin to consider supply chain involvement! Thankfully, ENOVIA provides exceptional, collaborative planning, development and release tools to help your organization plan your definition of success.

Connect BOMs (Bill of Materials) and other deliverables for better communication between Designers and Project Engineers. Share and discuss issues directly over your 3D designs. ENOVIA also brings powerful Sourcing and Product Management tools to the table which help you to synchronize efforts in-house and across your supply chain.

What is Digital Manufacturing?

Digital Manufacturing drives manufacturing innovation and efficiency by planning, simulating, and modeling production processes in the virtual world.

What if all the flaws and potential waste that only become evident during or after manufacturing could be identified at the earliest stages of the process? This is where Virtual Twin technology comes in to play.

Developing and building an accurate digital version of a factory, a product and the operational assets that create the product can have a huge positive impact on the success of manufacturing processes, effectiveness and viability.

Imagine building the factory and products virtually, being able to simulate and optimize new manufacturing system designs, as well as validate production schedules before even setting foot into the actual production facility.

What is a Digital Twin?

Gartner Group define a Digital Twin as:

“A digital representation of a real-world entity or system. The implementation of a digital twin is an encapsulated software object or model that mirrors a unique physical object, process, organization, person or other abstraction.”

Digital Twins are gaining recognition and popularity as a solution for digitally representing a product, building or even a human being. This is enabling new opportunities to improve performance, operations, productivity, or quality of life.

Implementing a Digital Twin strategy to drive sustainability programs can be profoundly effective. Digital Twins offer significant benefits when planning, implementing, and realizing:

- Reduced energy consumption

- Reduced material consumption and the switch to more sustainable materials

- Workforce activity optimization – travel, server usage, etc.

- Automation and robotization of hazardous and/or repetitive tasks to improve working conditions and health

Furthermore, Digital Twins provide several advantages in the recycling of a product based on a comprehensive and digital description, allowing for strong traceability and the efficient and controlled dismantling and recycling of material. Discover more about the advantages of a Digital Twin strategy for sustainable product creation in the Addnode Group report.

What is DELMIA 3DEXPERIENCE?

The 3DEXPERIENCE platform is a collaborative platform. It provides digital continuity to empower every organization in your company – from marketing to sales to engineering.

DELMIA 3DEXPERIENCE enables manufacturers to create digital models that virtually simulate products, processes, and factory operations. It incorporates Product Data Management (PDM) and Product Lifecycle Management (PLM) through ENOVIA with the additional integration of Dassault Systèmes’ other brands such as SIMULIA for Simulation, CATIA for Computer-Aided Design, and more.

There are a number of different manufacturing tools and applications which are included within DELMIA 3DEXPERIENCE:

- Process Engineering

- Ergonomics

- Robotics

- Machining

- Additive Manufacturing – Powder Bed & Deposition

- Plant Layout

- Virtual Factory

Read more about Digital Manufacturing with DELMIA in our blog post, “What is DELMIA?”

What is 3DEXPERIENCE?

Dassault Systèmes describe 3DEXPERIENCE as a Business Experience Platform which provides applications and services that enable digital transformation to a data-driven, model-based environment.

What this means is that the 3DEXPERIENCE platform brings together people, processes, and data in a cloud-based environment to help make collaboration simple for all your teams. Empower your organization with industry-leading solutions from product innovation, design, and development through to manufacturing, marketing, and delivery.

The 3DEXPERIENCE platform provides the underpinning apps and services that enable the transformation to a digital, data-driven, model-based environment. The common apps and services provide an effective way to connect everyone early in the innovation process.

3DEXPERIENCE enables you, your teammates, and interdepartmental colleagues to:

- Easily access all the latest information needed for your daily work on one platform,

- Fluently and seamlessly cooperate,

- Efficiently navigate large amounts of data,

- Share a stake, revise, and refine vital business processes.

How to Implement a PLM Solution

From the first idea to the finished product, its delivery and use through to its disposal, companies produce vast quantities of data. Without Product Lifecycle Management (PLM), this flood of data can be difficult to manage.

Selecting the appropriate PLM solution is the first step. It need to be appropriate for both the concerned corporation and medium-sized businesses. Additionally, it must to be adaptable enough to allow for future adjustments.

It’s crucial to strike the right balance between methodical approach and quick deployment. However, two instances that can be problematic in practise are highlighted by our experts:

- Without clearly defining its PLM project’s objectives, the organisation is racing to deploy PLM.

- The business meticulously plans out a master strategy that is future-focused. The criteria for this, however, have already passed before the idea step is finished.

Take a look at the fundamental stages of PLM implementation.