Benefits of Digitalization

Operational efficiency

By digitizing processes and workflows, industries can achieve significant gains in efficiency. Automation of manual tasks reduces human error and frees up employees to focus on more strategic work. Minimize downtime and extend the lifespan of assets using predictive maintenance, powered by the IoT (internet of things) and analytics.

Data-driven decision making

The use of big data and analytics allows industries to make informed decisions based on real-time data. This leads to better resource management, forecasting, and strategic planning. Digitalization transforms data into a valuable asset that can be monetized and used to drive innovation.

Improve customer experiences

Digitalization enables industries to engage with customers through multiple digital channels, offering personalized experiences and services. This not only improves customer satisfaction but also opens up new avenues for revenue through targeted marketing and sales strategies.

Agility and innovation

Digital technologies foster a culture of innovation, allowing industries to rapidly develop and deploy new products and services. Agile methodologies and digital platforms facilitate quick responses to market trends and customer needs, ensuring that businesses remain relevant and competitive.

Workforce transformation

Digitalization reshapes the workforce by necessitating new skills and competencies. It promotes a more collaborative and flexible work environment, often supporting remote work and global teams. This cultural shift is essential for attracting and retaining talent in the digital age.

Sustainability

By optimizing resource use and improving process efficiency, digitalization contributes to more sustainable industrial practices. It can lead to reduced energy consumption, lower emissions, and a smaller environmental footprint.

Risk management

Digital tools can enhance security and compliance, helping industries manage risks more effectively. Cybersecurity measures, for instance, are crucial in protecting sensitive data and maintaining trust in digital systems.

Globalization

Digitalization breaks down geographical barriers, enabling industries to operate on a global scale. It facilitates international collaboration, supply chain management, and access to global markets.

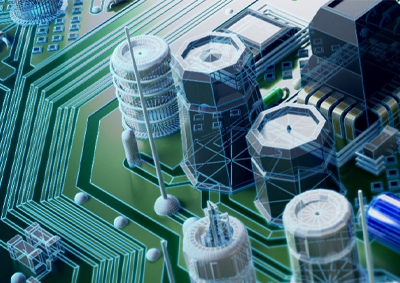

Industrial Digitalization Technologies

The Internet of Things (IoT)

The Internet of Things (IoT) is an emergent trend that connects everyday objects with the internet. These devices collect data and send it back to the cloud where it can be analyzed. This allows companies to make better decisions and improve efficiency.

Artificial Intelligence (AI)

Early AI adopters use practical Machine Learning (ML) solutions to provide commercial value. As this technology has advanced, organizations now use Deep Neural Networks (DNN) to plan ahead and prepare solutions in advance of new company demands arising.

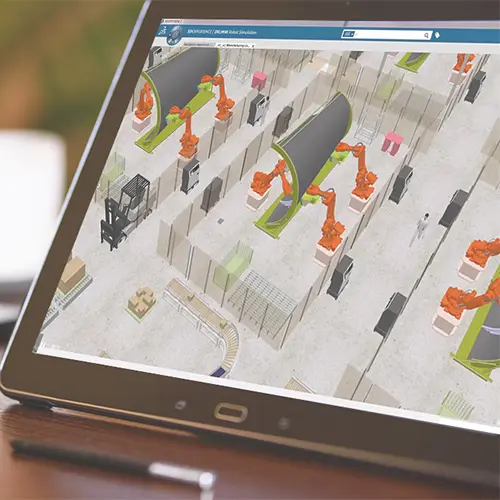

Robotics

Robotics are becoming increasingly common in factories across the globe. They’re being used to perform tasks that were previously done manually, such as welding, painting, and assembly. This means that workers can focus on higher value activities instead of repetitive tasks.

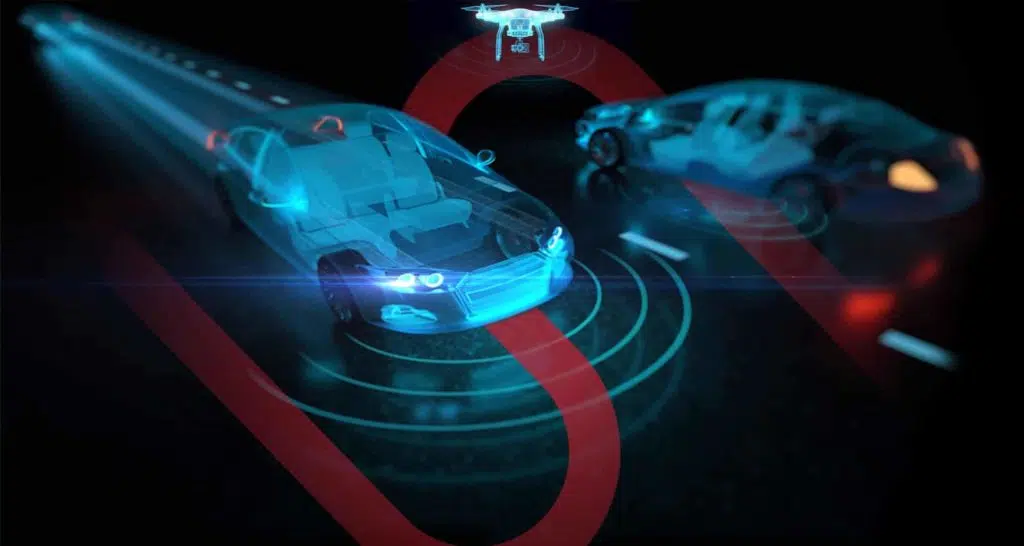

Autonomous Vehicles

Low level autonomous vehicles can help reduce driver error, while higher levels of autonomy have the potential to reduce risky and dangerous driver behaviors. Mass automation of our transportation systems may lead to a substantial reduction in traffic congestion and pollution.

Cloud Computing

Cloud computing is one of the biggest trends in tech today. It’s a model where companies rent out computing power rather than buying it outright. This means that instead of having to purchase expensive hardware, software, and maintenance, businesses can pay as they go.

Nanotechnology

There is a wide variety of applications for nanotechnology, due to the broad range of nanomaterials. Most commonly, carbon nanotubes are used in many industries for manufacturing extremely lightweight products with high wear resistance and break strength.

Biotechnology

Biotech products and manufacturing processes are advancing rapidly. This is particularly evident in the pharmaceutical industry. Examples include 3D-printing of human tissue, and the use of enzymes and microorganisms to manufacture a wide variety of products from textiles to biofuels.

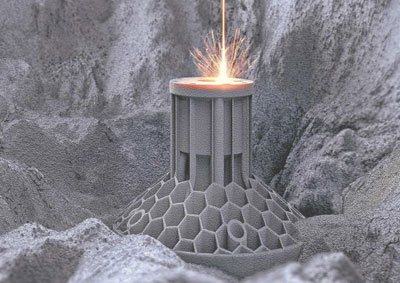

Additive Manufacturing

3D printing can either be done using the additive manufacturing method which involves building up layers of material, or by cutting from a bigger block of material in subtractive techniques. These are each more sustainable methods as they reduce the amount of material waste.